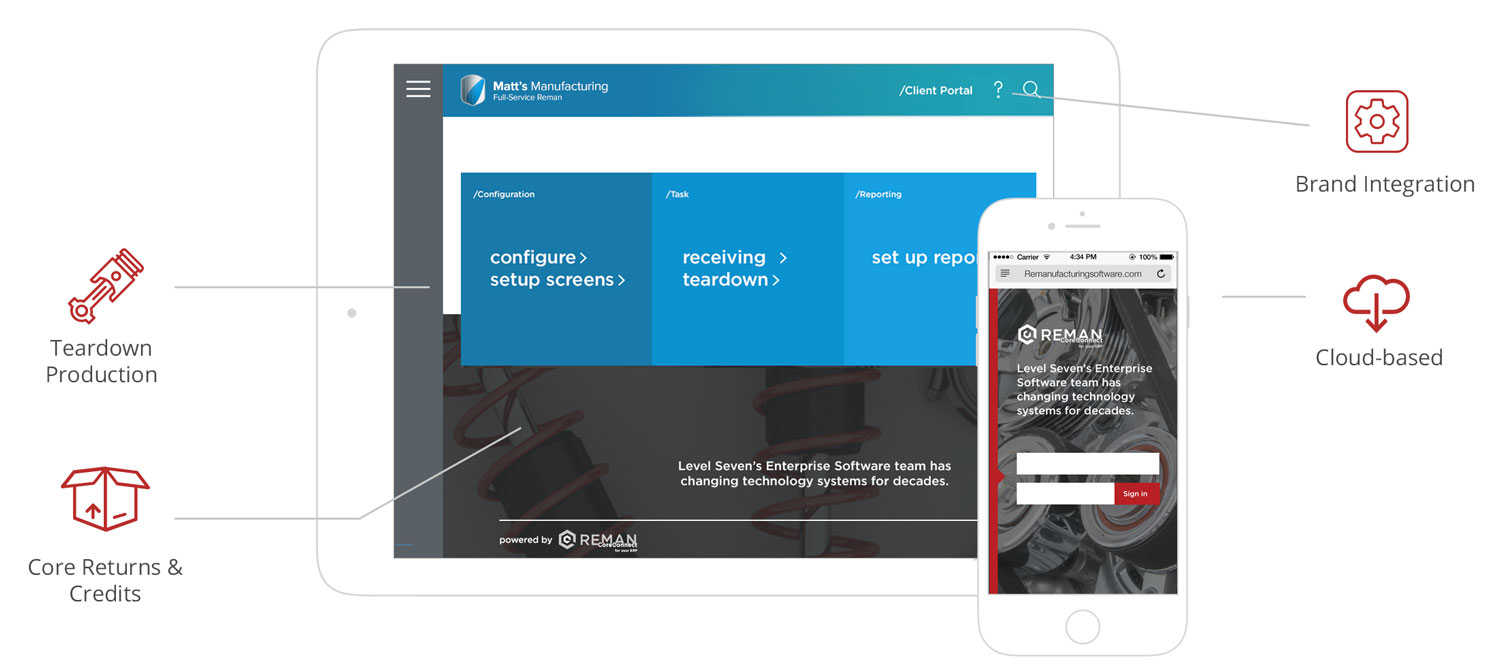

CONFIGURATION FEATURES

Customer Portal

RemanCoreConnect™ utilizes a customer portal that provides insight into the core history and core eligibility of the customers of the remanufacturer. With this portal, customers are able to log into the system and view a list of all cores they have bought from the remanufacturer, the core due dates, and core history. On the remanufacturer side, the remanufacturer can also login and view all outstanding cores owed by all customers.

ERP Integration

RemanCoreConnect™ connects to any major ERP System in order to ensure safe and effective data handling, uploading, and reporting regarding all remanufacturing operations.

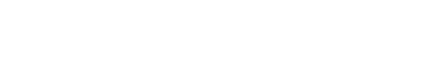

Brand Integration

RemanCoreConnect™’s custom branding allows for the system to be setup to match the custom colors and branding associated with the remanufacturer.

Core Terms

RemanCoreConnect™ can be set up to allow users to set specific core terms per customer. As a result, based on previous receiving analytics, the core terms can be updated and individually set to ensure improved core returns.

TASK FEATURES

Teardown Production

RemanCoreConnect™ tracks a core through the entirety of the remanufacturing teardown process. With RCC, users are able to track a core as it moves throughout teardown, enhancing the overall core tracking process.

Receiving

RemanCoreConnect™ is setup to track a core once received from a client. The system can be set to notify both the facility and customer once a core has been received and is ready for inspection and teardown.

Core Returns

RemanCoreConnect™ gives the customers of the remanufacturer the ability to schedule a time and location for core pickups, thus improving the efficiency and efficacy of core returns.

Core Inspection

This solution allows organizations to inspect each returned core through an included inspection sheet. This inspection includes grade, a checklist of items, comments, and pictures, and is downloadable via a PDF.